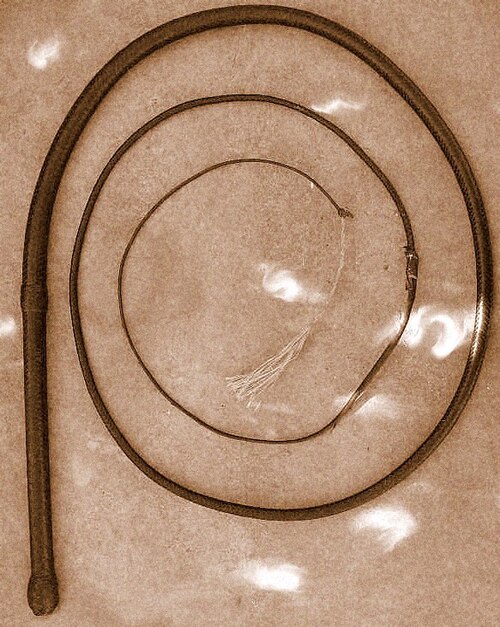

What is the bullwhip effect? The bullwhip effect is where a small change in consumer spending can lead to a very large fluctuation down the supply line. It is one of the causes of overproduction and waste. It is called the bullwhip effect because a small flick on the handle of a whip can lead to larger and larger waves further down.

The problem comes because suppliers have to constantly monitor demand and react to it. Let’s take chocolate bars as an example. Every month, Steven’s Chocolate Bars Company sells one million of their chocolate bars. That means their supply line is set up to produce those one million bars with as little waste as possible. Wasted resources mean lost profits. The ingredients for that chocolate bar, the cocoa, the milk, the sugar, and the peanuts, all come from different suppliers. As does the plastic used for the wrappers and the cardboard used to box them.

This month, there is a football match in town, and people come from all around. After the game has finished, they all buy chocolate bars, and Steven’s Chocolate Bars Company suddenly sells 5% more chocolate bars than they usually do. The stores that sell the chocolate bar see that supplies are running low and they contact Steven’s Chocolate Bar Company, which increases production by 10% to make up for the sudden demand. They don’t know why, but if their chocolate bar sells out, customers will buy other chocolate bars, and they may never come back. They contact their supply chains and ask for more ingredients. These suppliers don’t want to be the reason why Steven’s Chocolate Bar Company can’t make enough chocolate bars, so they all increase their supply by 15%. The small change at the beginning of the supply chain amplifies as it gets further and further away because each link needs to provide more than enough for the link above it. Each level is trying to predict the demand with limited information, which leads to them adding safety stock. This is the bullwhip effect.

It doesn’t sound so bad, but demand falls back to normal levels, and Steven’s Chocolate Bar Company now has too many bars that it cannot sell, and each link up the chain has now produced too much that they can no longer sell. This is all wasted. The bullwhip effect causes a waste of food or whatever resources are in the supply chain, all because of the fear of not being able to produce enough. The problem is not just the resources, but the lost investment in inventory, which can even lead to people losing their jobs and bankruptcy. The effects ripple outwards as well. The company that produces the milk might reduce its supply to X company so that it can provide more milk to Steven’s chocolate bar company, and that might have knock-on effects as well.

This happened in 2020, with the rise of COVID-19 and panic buying of toilet paper. Toilet paper sales went up several hundred percent and stores very quickly ran through their stocks, which just added to the panic buying. The supply chain responded, but by then sales had dropped back to normal, in fact even lower than normal because people had hoards of toilet paper, and the stores were swamped with toilet paper. Toilet paper isn’t quite as bad, though, because it doesn’t have a best-before date.

The best way to deal with and mitigate the bullwhip effect is rapid communication along the entire supply chain. This has improved over the years as communication has become faster and the amount of available data has risen. AI systems also allow the supply chain to monitor the rise and fall of demand in real time and react to it in appropriate amounts. Walmart runs a system like this where they can analyze the data as it comes in from the cash registers. They know how much is in each store, each warehouse, and they can manage the supply chain appropriately. Walmart does have the advantage of controlling its entire supply chain, but they do show that it is possible. Prices are very important to Walmart, and keeping the bullwhip effect in check is a great way of saving money.

The bullwhip effect has always existed, but it became more significant as supply chains grew longer and more global in the late twentieth century, when logistics and information systems made it possible to react quickly — and therefore to overreact. Supply chains before this were generally local and in no way fast enough to react to an increase in demand, unless it was a long, slow increase.

Sources

https://www.investopedia.com/bullwhip-effect-definition-5499228

https://www.shipbob.com/blog/bullwhip-effect

https://en.wikipedia.org/wiki/Bullwhip_effect

Image By Cgoodwin – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=3759427