How can you 3D print metal? You can 3D print metal in the same way you can 3D print plastic. It has to be melted in some way, shaped, and then allowed to harden.

Plastic 3D printing has been around for a while, and there are several different kinds. The cheapest and the most basic kind have a spool of plastic wire that is fed through a heated nozzle. The plastic melts and the nozzle moves around, printing layers of plastic. This is the cheapest, but it sets in layers, and you can not only see the layers, but they are weak points in whatever you are printing. A more expensive and better method is to have a bowl of light-sensitive resin, with a movable frame over a light source at the bottom. The movable frame opens and closes, allowing light through in specific places, hardening the resin. An arm pulls the hardened resin up slowly as the shape is formed from the top down. This is much stronger, but more expensive.

In a similar way, there are three different ways of 3D printing metal, and they all vary in cost and strength. The cheapest and easiest way is to use metal mixed with a binder. Having a heat source inside the 3D printer can be very costly because metal melts at a much higher temperature than the plastic used in 3D printers. A plastic 3D printer usually uses PLA, which melts at about 160 ℃. Metal 3D printers can use a variety of metals, and the lowest melting temperature is aluminium at 660 ℃. If they use copper, the melting temperature rises to 1084 ℃. To get around this, the cheapest type of metal 3D printer prints with a mix of metal powder and a binder. This is called Binder Jetting. Once the shape has been laid out, it is heated in a separate kiln to melt it. This produces the metal shape, but the binder inside the metal is a weak point, and this type of printing can’t be used for anything structural.

The second type of 3D printing uses a wire similar to plastic 3D printing, but it is not a wire made of solid metal. The wire is made of a metal powder that is bound in a layer of plastic to keep it together. This is called Bound Metal Deposition. The difference between this type of printing and the previous is that here the binder is removed. The metal wire is fed through the 3D printer nozzle, where it is heated to the melting point. The printer nozzle traces out the shape. Once the object is made, it is placed in a heated solvent bath to remove the plastic. The whole object is then placed in a kiln to burn out the rest of the plastic and to fully solidify the metal. The printed object shrinks during this stage, so it has to be printed larger than the final required size to take this into account.

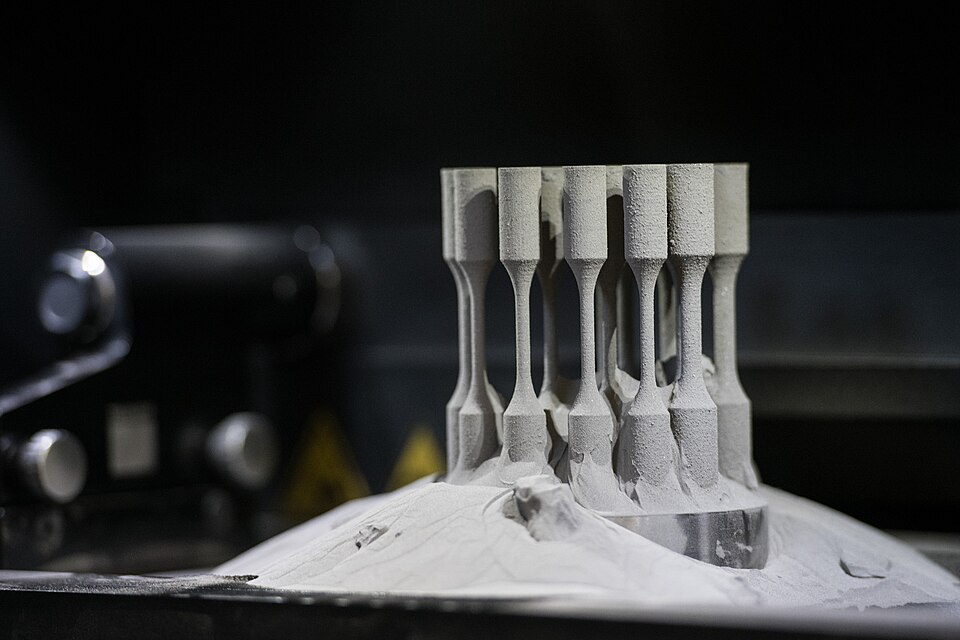

The final type, and probably the best, uses powder and a laser. This is called Laser Powder Bed Fusion. Metal powder is spread over the base tray of the printer by an automatic arm. The whole printer has to be inside a chamber that has been purged with an inert gas, such as argon, so that the metal powder doesn’t stick to other things or oxidize. A laser at the top of the printer then traces out the shape to be printed in the powder at the bottom. The energy in the laser melts the powder only in the places where it is needed, and that builds up a shape. After a layer has been finished, the base of the printer drops by one layer, and the automatic arm spreads another layer of powder. The laser then melts this, sticking it to the bottom layer of metal and extending the shape. Through this process, the printer can build whole shapes out of only metal, with no troublesome binders. This makes the shape very structurally strong, and it is the best method.

However, there are two problems with this method. The first is that metal powder is very expensive. 1 kg of stainless steel powder costs about $400. 1 kg of solid stainless steel of the same quality costs about $7 at the moment. The second problem is that loose metal powder is very dangerous. Any kind of powder can be flammable if not treated carefully, and there is the risk of explosions. Metal powder is also very dangerous for people because if it is inhaled, it can cause massive damage to the lungs. The powder has to be treated very carefully, which adds to the cost of the build. The powder is expensive because it is highly complex to produce. It is made by atomizing the metal with a gas, which is difficult and requires a lot of energy. This drives up the cost. In the future, there will be far more efficient ways of printing with metal. And this is what I learned today.

Sources

https://www.ramlab.com/resources/ded-101

https://www.waam3d.com/learn-waam

https://www.hubs.com/knowledge-base/introduction-metal-3d-printing

https://www.metalsupermarkets.com/melting-points-of-metals

https://www.metalsupermarkets.com/melting-points-of-metals/

https://en.wikipedia.org/wiki/Fused_filament_fabrication

https://markforged.com/resources/blog/how-the-metal-fff-3d-printing-process-works

https://www.fastwell.in/316-stainless-steel-supplier-manufacturer.html

Image By René Volfík – Institute of Physics of the Czech Academy of Sciences, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=141136042