I learned this today. Spot welding was discovered by accident by Elihu Thomson in 1877 when he was giving a lecture on electricity and accidentally passed a current through two pieces of wire.

Spot welding is obviously a form of welding. Welding is the process of joining any two pieces of metal together through heat. General welding works by heating a welding rod to a very high temperature so that it melts. This melted welding rod is used as a seal to fasten two pieces of metal together. This is called stick welding and it works by passing an electric current through metal and an electrode. The electrode melts and it combines with the metal to form a joint.

Most welding forms use a melted metal to create a metal joint. Spot welding doesn’t do that. It welds sheet metal together by joining two surfaces of the material with heat. It does this purely with electricity.

Spot welding is also caused “resistance welding” because it works using the resistance properties of metal. Resistance is the measure of its opposition to the flow of electric current. A very conductive material has a low resistance and a material that doesn’t conduct electricity well has a high resistance. The unit of electrical resistance is the ohm (Ω). Silver is the best metallic conductor of electricity and has a low resistance. Tungsten has a very low conductivity and a very high resistance.

When an electric current flows through a material the electrons hit atoms, other electrons, or impurities. These collisions are electrical resistance. The more likely collisions are, the higher the resistance. When the electric current is applied to the material, it accelerates electrons, giving them kinetic energy. When these electrons hit atoms or other parts of the material’s structure, they transfer their energy to the material, producing heat. Metals with a high electrical resistance heat up very easily when a charge is applied. That is why nickel and chromium alloys are used in toasters. They have a high resistance and heat up quickly.

Spot welding (resistance welding) makes use of this property. Two shaped copper alloy electrodes are used. The electrodes are pressed onto the surface of the metals that are to be welded. A current is applied through the electrode for about 0.5 seconds. The current is then switched off. The current flowing through the metal meets resistance and heats the metal to about 1400℃. The two surfaces of the metal melt, mix with each other, and set as one when they cool.

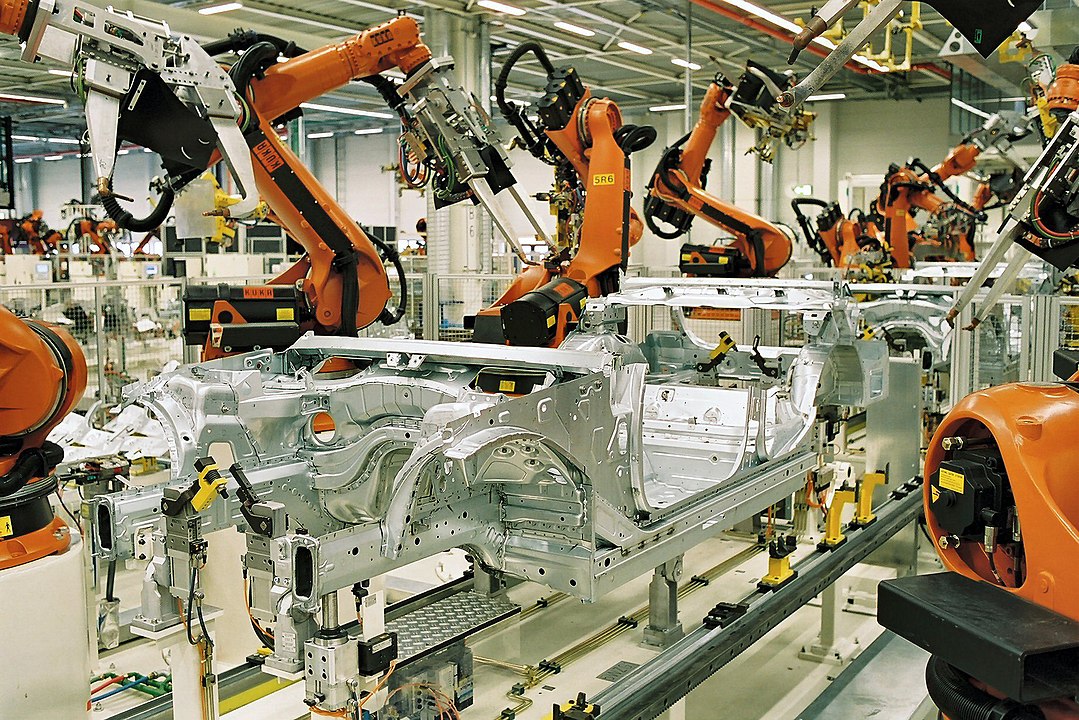

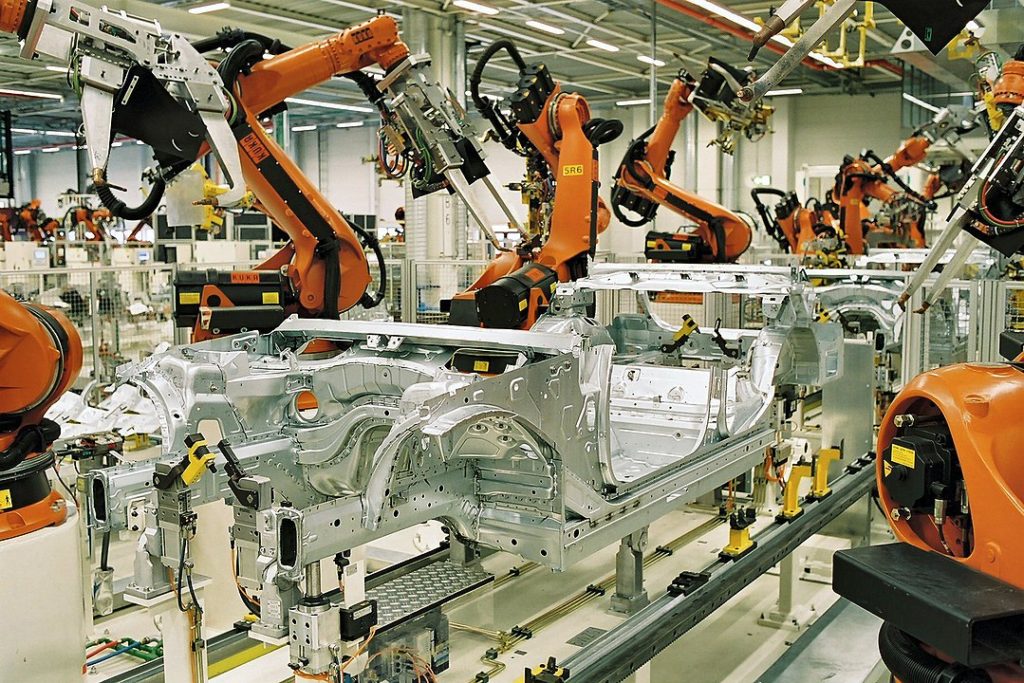

Spot welding is very precise and can weld thing sheets of metal together extremely quickly. It requires no filler materials and is environmentally friendly. The joints it produces are strong and reliable. For these reasons, spot welding has become the mainstay of car manufacturing plants. Robots spot weld parts of a car together. The average car contains about 5000 spot welds, holding all of its pieces together. Spot welding is extremely fast, but more than that, it is the only form of welding that can be used with the thin aluminum panels that are used in cars. Any other type of welding would burn through the metal or warp it.

Spot welding was discovered by Elihu Thomson in 1877. As he young boy he became interested in electricity when he bought a book on magic. The book explained how to use electricity to perform magic tricks and it explained how to make an electrical machine out of a wine bottle. Elihu built this and many other contraptions. He became fascinated by electricity and went on to research electrical engineering and invent. During his lifetime, he held over 700 patents. The company he started with a colleague of his, Edwin J. Houston went on to become General Electric, the 33rd largest firm in the United States.

When Elihu was lecturing at the Franklin Institute at Philadelphia in 1877, he passed a current through an induction coil while another coil was resting on it. When he went to pick them up, he realized that they were welded together. It didn’t take him long to work out why, but it took him a little longer to build the first electric welder. By 1885, he had worked out how to do it successfully and built the first spot welder.

So, spot welding works because the resistance to electric current in a metal causes the release of heat. This heat can be used to melt two metals so that they weld together when they cool. This process was discovered by Elihu Thomson when he accidentally ran a current through two wire coils while they were touching. He realized what had happened and built an electric welder in 1885. That invention is now used in countless places, most prominently in car manufacturing plants. Without it, it wouldn’t be so easy to make cars. And this is what I learned today.

Sources

https://www.schuettemetals.com/blog/resistance-welding

https://en.wikipedia.org/wiki/Spot_welding

https://surehand.com/blog/welding/history-of-mig-and-spot-welding-in-car-manufacturing-industry/

https://en.wikipedia.org/wiki/Joule_heating

https://en.wikipedia.org/wiki/Electrical_resistance_and_conductance

https://askinglot.com/how-hot-does-a-spot-welder-get

https://en.wikipedia.org/wiki/Elihu_Thomson